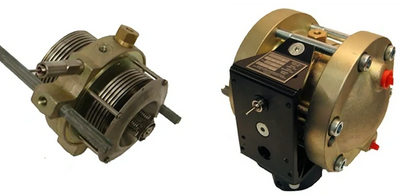

ITT Barton Model 199 DPU

Product Summary

Although they differ in construction details, the Model 199 and Model 224C DPUs incorporate the same basic features. Both consist of a Bellows Unit Assembly (BUA) and removable pressure housings.

In both models, flexible bellows are secured to a center plate. The movable bellows are rigidly connected by a dual valve stem that passes through the center plate.

Valve seats in the passage through the center plate form a seal, with the valves spaced on the stem. A drive arm pivoted on the end of a sealed torque tube contacts the valve stem in the center plate.

The interior of the bellows and center plate are filled with a clean, non-corrosive, low

freezing point liquid. A free-floating bellows is attached to the high-pressure

bellows to allow for expansion or contraction of the fill liquid, thus providing positive

temperature compensation. If the bellows are subjected to a pressure difference

greater than the differential pressure rating of the unit, a valve mounted on the

center stem seals against its corresponding valve seat. As the valve closes, it “traps”

the fill liquid in the bellows; thus, the bellows are fully supported and cannot be

ruptured regardless of the overpressure applied within the limits of its safe working pressure. Since opposed valves are used, protection against “over-range” is provided in either direction.

Pressure is applied to the high and low chambers surrounding the bellows. Any difference in pressure causes the bellows to move until the spring effect of the unit balances out. The linear motion of the bellows (proportional to the DP) is transmitted as a rotary motion through the torque tube assembly.

Components

Bellows Construction - Individual diaphragms, stamped and formed from 316 stainless steel or Inconel, are assembled using a resistance welding technique. The results — exacting linearity characteristics, a long cycle life, and freedom from effects of work hardening—commonly

encountered with the hydraulically formed or mechanically rolled types.

Temperature Compensator

An auxiliary free-floating bellows attached to the HP bellows automatically protects the unit from zero/calibration drift when ambient temperature changes. Pulsation Dampener (Model 199 Only) The pulsation dampener in the M199 is externally adjustable and provides for direct control of the instrument's response time from approximately one second to several minutes for full-scale travel of the bellows.

Self-Draining/Venting Connection

Designed on the top and bottom of the housing, these connection ports provide automatic liquid draining or venting of gases.

Calibration Springs

The range springs' strength determines the unit's differential pressure range. Each range-spring assembly is stamped with the DP range it produces. They have an extremely low

hysteresis characteristic and exceptional temperature stability.

External Bellows Sensors

For applications requiring external sealed sensors, such as: corrosive, high

temp. and dangerous fluids, many options are available. Please consult us to determine the best type for your application.

Differential Pressure Instruments Inc.

1619D Diamond Springs Rd Virginia Beach, VA 23455